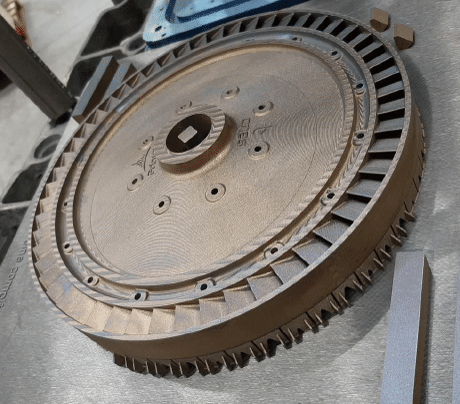

Inconel turbine disk for launcher

Designed to survive the harsh conditions of a rocket engine turbine, the disc maintains a lightweight structure thanks to the internal network of additively manufactured lattice structures that make up the disc’s bones.

CNES collaborated with PrintSky, a joint venture between Sogeclair aerospace and AddUp, to print a turbine disc with a lattice structure. LBM (Laser Beam Melting) technology, similar to the DMLS (Direct Metal Laser Sintering) process, offered the space centre the possibility of manufacturing this part in inconel, a superalloy based on nickel, chromium, iron, magnesium and titanium. This material is one of the most widely used for aerospace applications, particularly for its resistance to extreme conditions. The mechanical and high-speed rotation tests of this disc should be carried out in the coming weeks.